What we do here at Prescott

Here at Pure Wafer Prescott, AZ, we primarily reclaim 100mm to 300mm silicon wafers. We take a silicon wafer that has been used for testing or calibration by our customers.

The wafers are visually inspected, chemically cleaned and sorted, then polished and sent into a cleanroom.

In the cleanroom, the wafers are inspected for particles and specially packaged for shipment back to our customers.

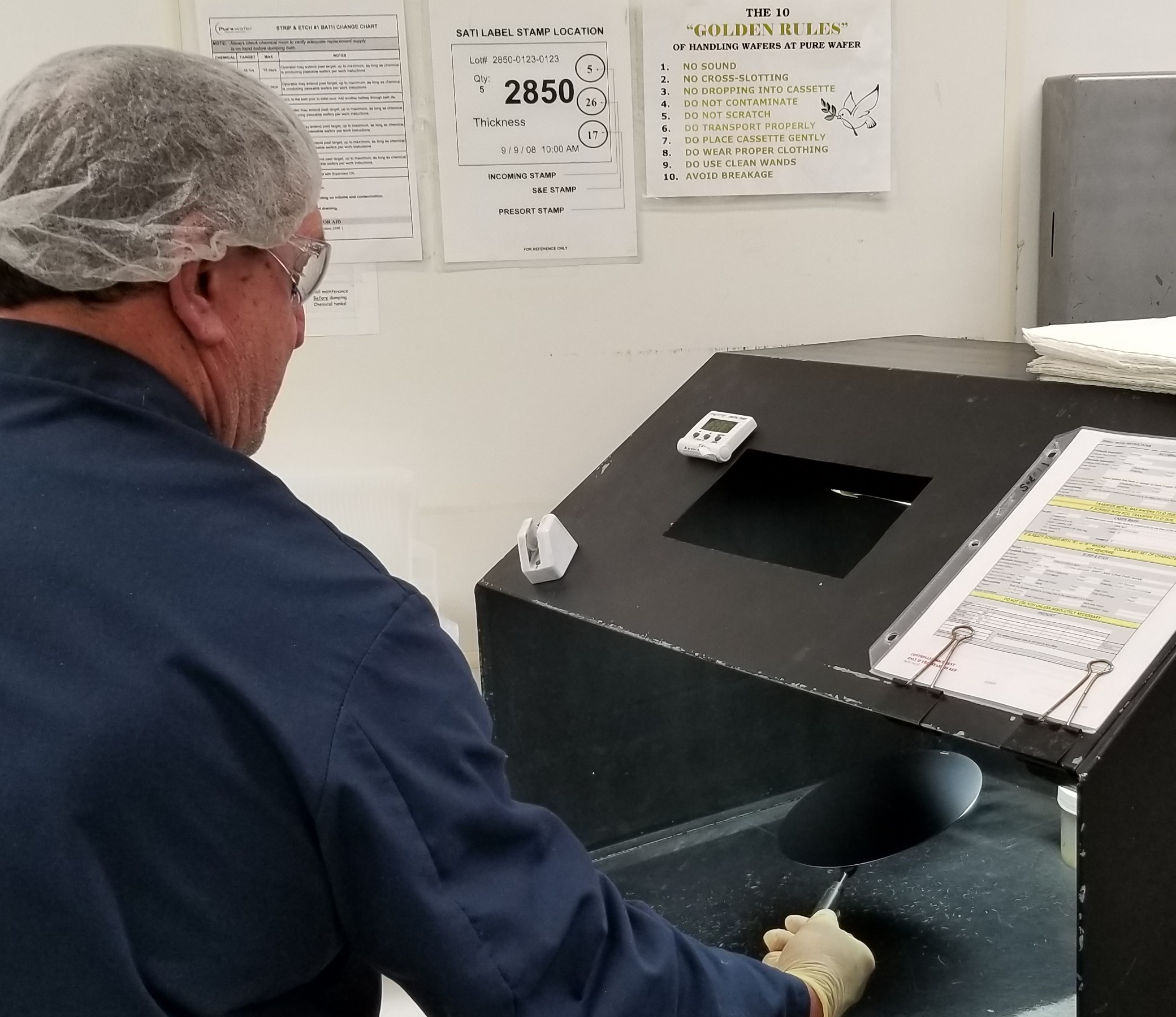

We first send the wafers to Incoming where they get sorted by film type and recorded into our system.

We then chemically strip the wafers and inspect them under a bright light.

Here is a video showing wafers getting clean through a small, wet bench.

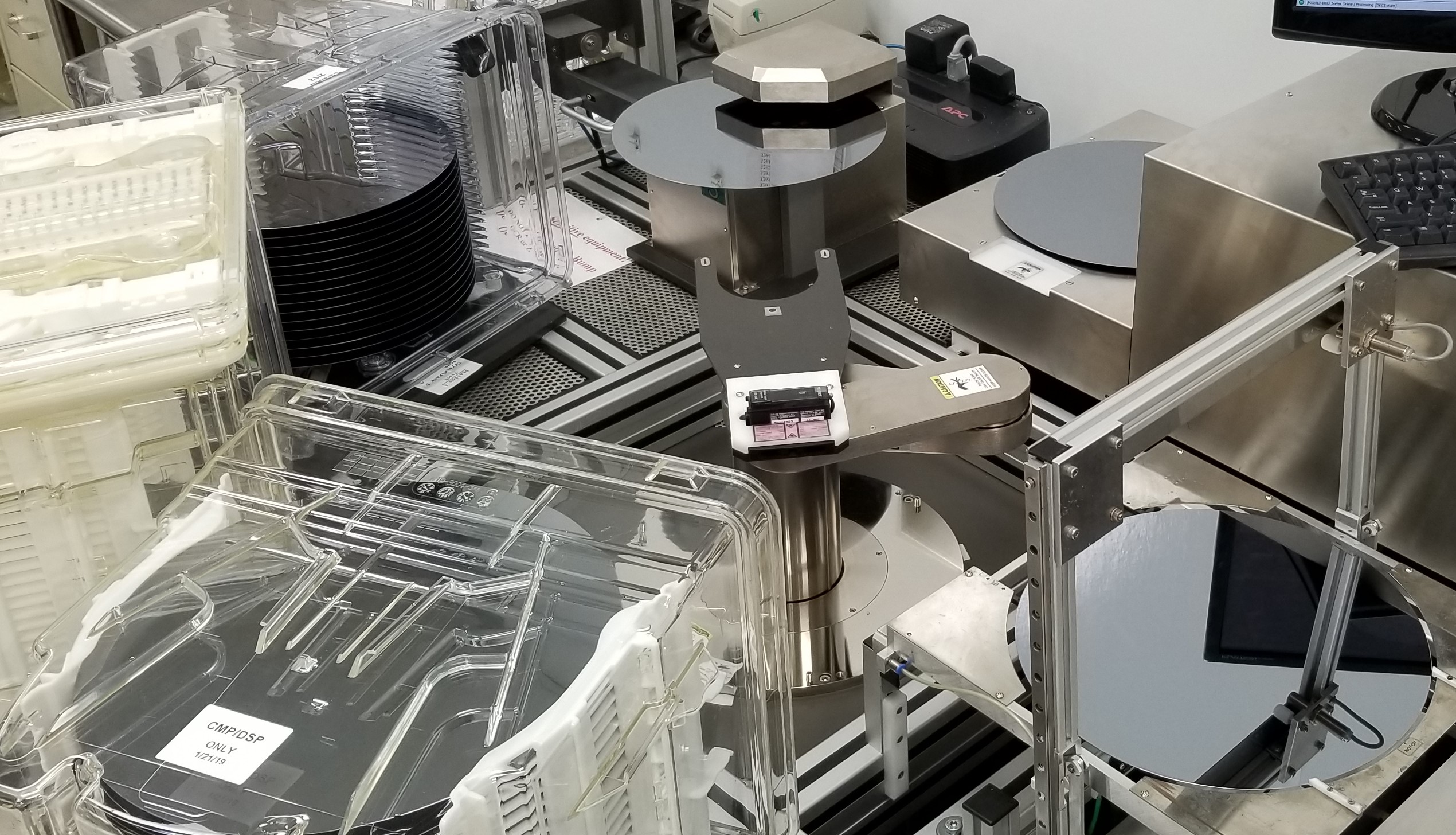

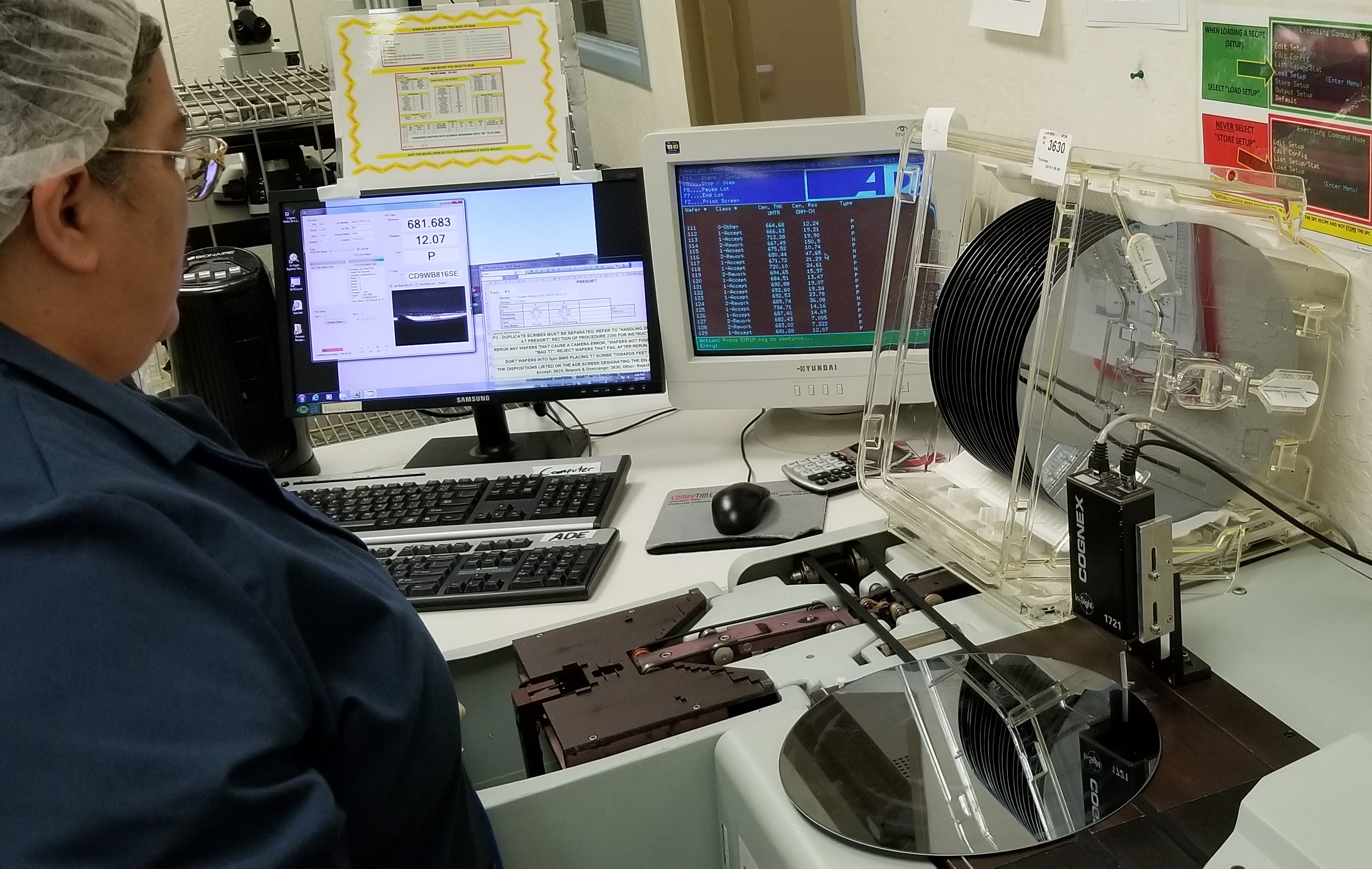

Then the wafers get measured for thickness and other properties using a variety of sort tools.

Now lets send them to be polished.

The final step is the cleanroom for final clean, inspection, and specialty packaging.

Pure Wafer Prescott, AZ has a Class 1 cleanrooms. A great video that shows cleanroom training and understanding of the protocols in a cleanroom.

In our cleanrooms, we measure particles down to 30nm. How small is a Nanometer?

Why partical size is important.

Where do they go after they leave Pure Wafer and how are they used?